After developing a love for Engineering just over two years ago, I have sought ways to further my knowledge of the engineering process through project based learning. This page gives brief descriptions of projects I have undertaken during my time at Rensselaer both in and outside course work. More information is available upon request, and feel free to contact me with any questions.

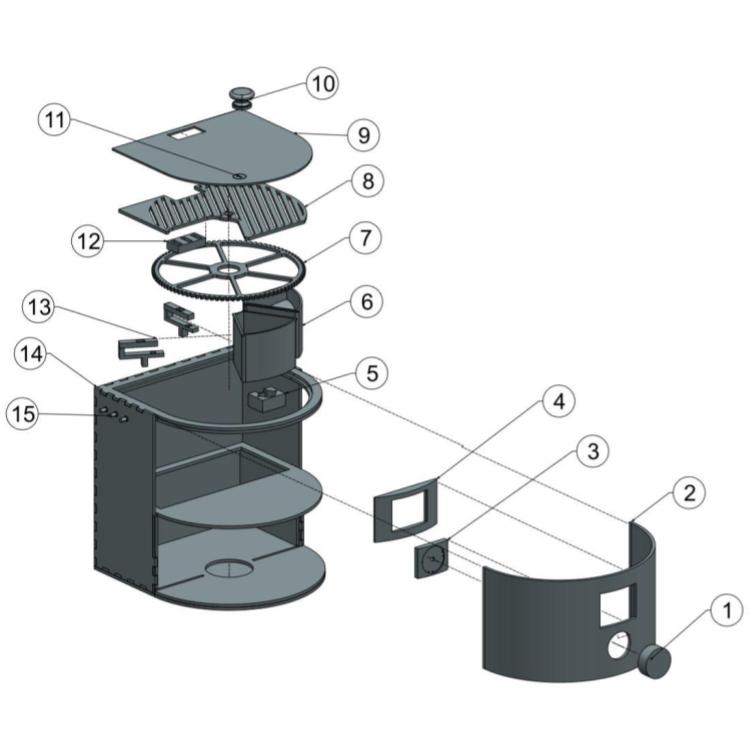

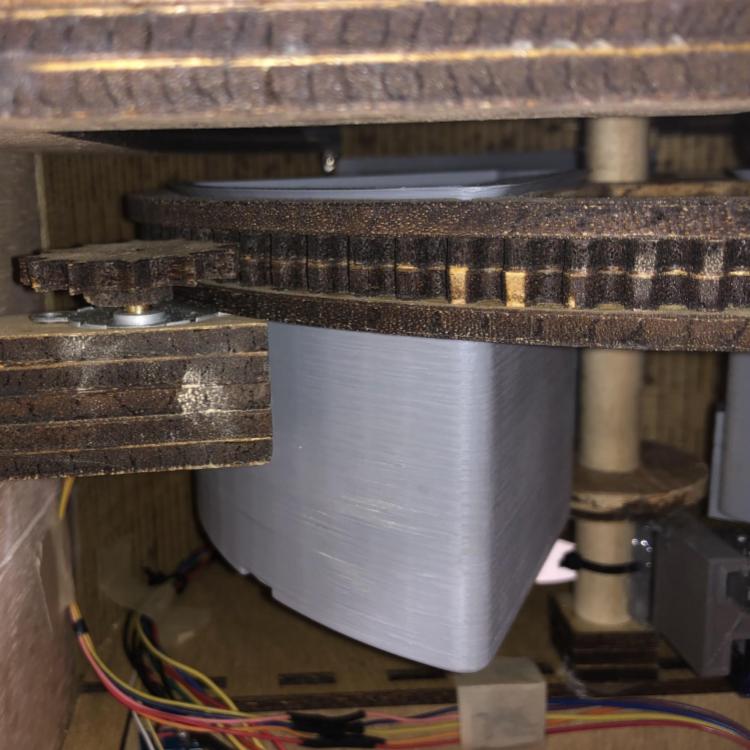

Working on a team of 6 in a class known as Intro to Engineering Design, we identified 3 issues associated with medication distribution: diverted medication, prescription drug abuse, and medical non-adherence. Working over 10 weeks, our team created a functional prototype (dubbed the "ProperDose") which would allow for the dispensing of the right pills to the right person at the right time. I worked in the design and fabrication of the overall external structure and internal cartridges as well as the building of a complete user interface and wiring of the electronics.

It was decided early on that the outer shell would be fabricated on a Laser Cutter out of plywood due to the high speed and accuracy. This, I achieved by redesigning the preliminary drawings to be a compatible outer shape for laser cutting, leaving most of the corners at 90 degrees and leaving just one section in the front curved to accomodate a "living hinge" laser cut design. Many of the internals were laser cut and glued in a stacked arrangement to reduce fabrication time due to the short project timeframe. After deciding on a Raspberry Pi for the platform of the ProperDose, I was tasked with providing a user interface as well as wiring the necessary electronics. The library WiringPi was used to control the GPIO pins. The user interface was split into two sections: a configuration page on a web server accessible from anywhere on any device, and a basic information-serving interface on the ProperDose's LCD.

At the end of the 10 weeks, the prototype worked near-flawlessly, taking input from the web application, counting down on the LCD, rotating to the correct cartridge of 6, and dispensing the correct amount of medication. The beginning problem statement had been answered - it is possible to create a medication distribution system that tackles the given three parameters for under $150.

Close Project

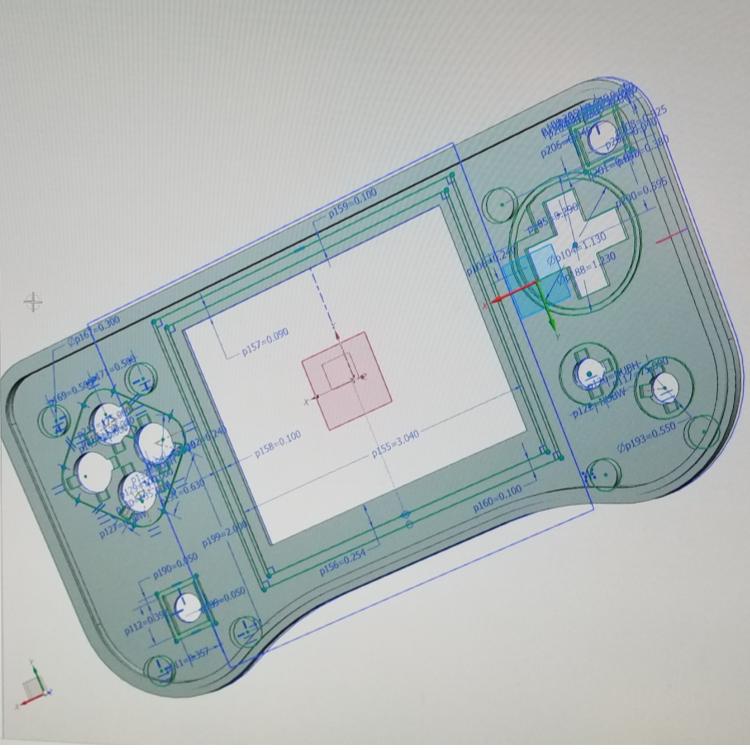

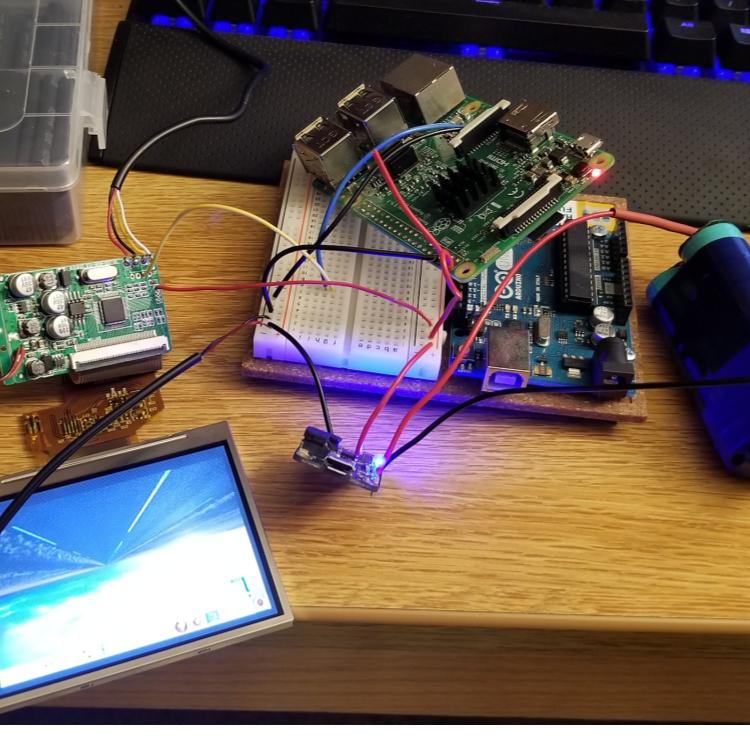

Inspired by my love for classic games such as those on the NES and Genesis as well as my fascination with miniaturizing hardware projects, a portable game emulator was the next logical step after completing a build of an arcade cabinet running on similar software. The project is based on the Retropie project for Raspberry Pi, but is built around a completely custom case (modeled in Siemens NX) and custom layout.

This project has been fantastic fun from start to (almost) finish(ed). Starting with knowledge on how to setup an emulating software on a Raspberry Pi and pair it with buttons routed to the GPIO pins, most of the project consisted of attempts to make internals small enough to fit inside a comfortable shell and guarantee battery draw would not be too high.

All of the electronics for the emulator are operational, including the battery circuit for charging and discharging the battery. The out shell was 3D printed and all the internals fit correctly, but I was unhappy with the overall finish of the 3D printed surface. A new outer shell is being drafted that allows for an easier post-processing experience so that the final touches can be added. The 3D models I designed can be viewed by clicking below:

Emulator Top

Attending the Maker Faire in New York City, I was in awe of many things - but my favorite event was the Power Racing Series. The Power Racing Series was the epitome of why I chose engineering. It is a racing series between people who have modified children's toys (Power Wheels mostly) to achieve high speeds and carry adult-sized passengers. The lunacy of the whole event drew me to it, but the unique engineering challenge of adapting a childrens toy for this competition is what really piqued my interest. (More info at the Power Racing Series website)

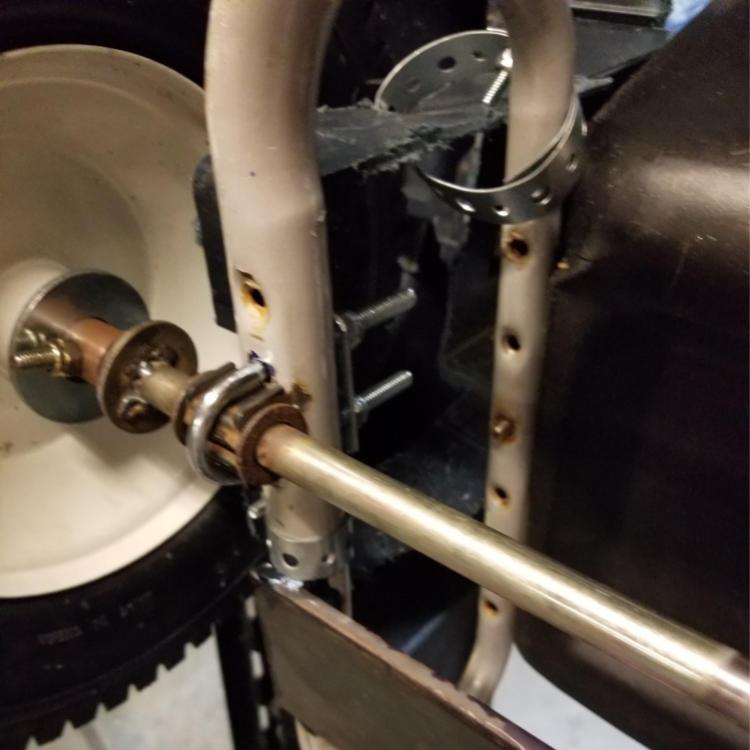

It started with the body of a Ford F-150 (a scale childrens toy version) bought off craigslist in Albany. From there, the steel frame of a pedal-powered go-kart from my childhood was used. Many steel reinforcements were added to the frame to make it withstand both our "larger than child-sized" stature and the heavy motors and electronics needed to accelerate the vehicle. Body was adapted to fit the frame and the many features of both (such as the steering rack) were reinforced.

Currently, the project is in-process. The project is in a "roll-able" state, as all the components are in place other than the means to accelerate and decelerate the vehicle. The size of motor and battery have been calculated and both are soon to be ordered. This project has been put on hold as a result of the suspension of the New York Maker Faire.

Close Project

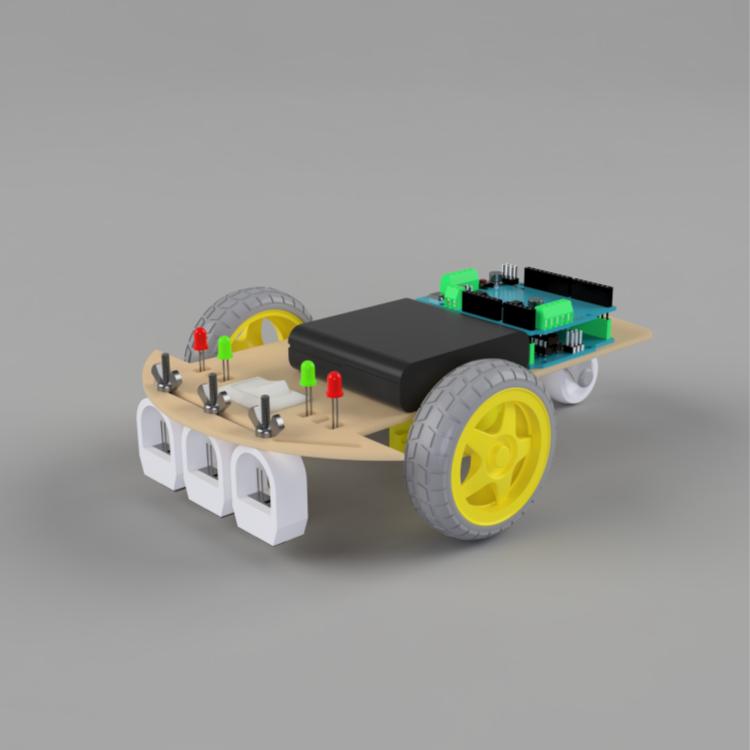

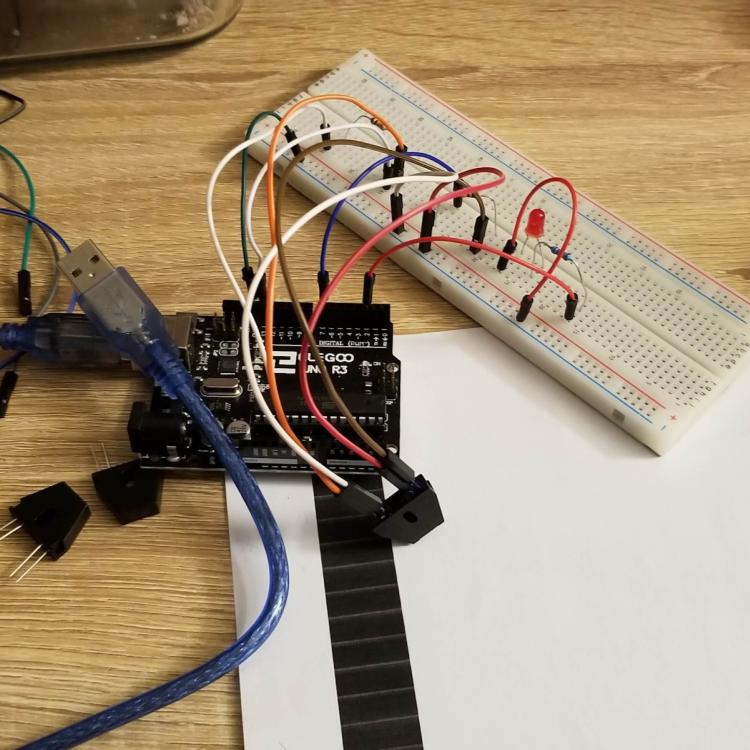

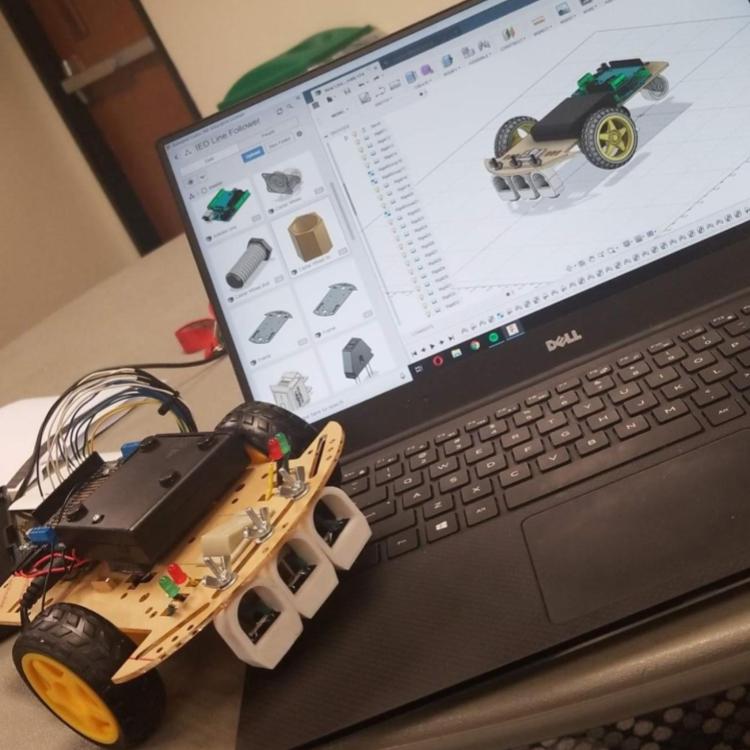

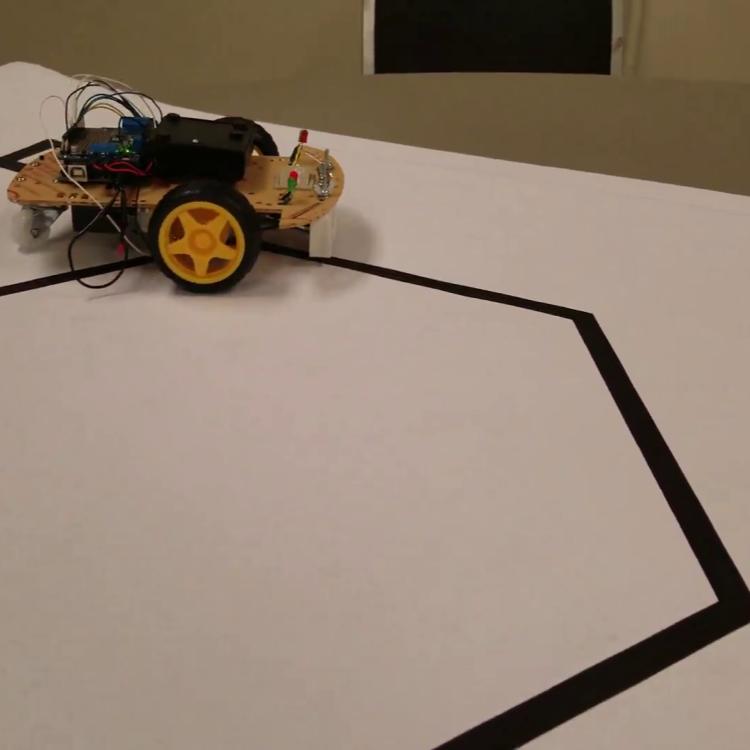

Placed in a team of 3, we were given the task to create a demonstration-ready line follower in just under 4 weeks. The resulting line follower had to navigate courses of increasing complexity in a set amount of time with elements such as intersections that required much iteration. I was assigned the task of the line follwer's electronics - including both the physical hardware connections to the board and the code (in C) as well as the fabrication of some of the components due to my familiarity with 3D printing and laser cutting. As an addition, I added bluetooth connectivity to start the line follower from any compatible device.

On demonstration day, the project worked extremely well, falling within all design parameters. Our line follwer's only failure was not being able to navigate the hardest-rated track within the time frame. We believe that issue to be due to the large size of the wheelbase, and on a further iteration, an overall smaller footprint would allow for tighter turns and higher speed due to increased accuracy.

Close Project